The future of work is not just about digital screens and virtual meetings; it’s about transforming traditional industries with cutting-edge technology, making hazardous jobs safer and more efficient. A recent demonstration in Tokushima, specifically in the region of Miyoshi, offered a powerful glimpse into this future, showcasing advanced remote control technology designed to conduct construction work with unprecedented levels of safety.

As an IT journalist, it’s thrilling to witness how innovation is pushing the boundaries of what's possible, fundamentally altering how we build our world. This isn't merely an incremental improvement; it's a paradigm shift with profound implications for workers, companies, and society at large.

The Dawn of a Safer Era: Why Remote Control is Essential

Construction has always been an industry synonymous with hard labor and, unfortunately, high risks. Workers often operate in challenging environments – think unstable ground, steep inclines, confined spaces, or areas prone to natural disasters. These conditions not only pose significant threats to human life but also contribute to labor shortages, as fewer people are willing to undertake such dangerous work.

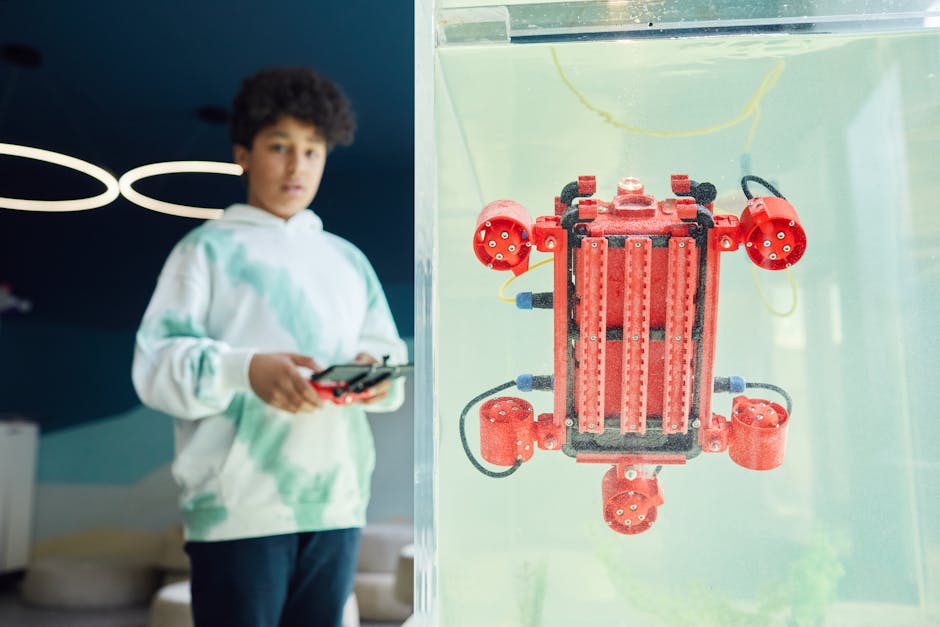

This is precisely where remote control technology steps in as a game-changer. By enabling operators to control heavy machinery and perform complex tasks from a safe distance, this innovation effectively removes personnel from harm's way. The demonstration in Tokushima, Miyoshi, highlighted a crucial step towards a future where human ingenuity guides machines without direct exposure to danger.

Bridging Distance, Enhancing Safety

The most immediate and impactful benefit of this technology is the dramatic improvement in safety. Imagine a construction site in a landslide-prone area or a structure that needs demolition in a hazardous zone. Instead of sending workers into these potentially lethal environments, skilled operators can now manage the entire process from a comfortable, secure command center, sometimes miles away. This not only protects lives but also reduces the physical strain on workers, potentially extending careers and improving overall well-being.

Furthermore, remote operation can allow for work to continue in conditions that would otherwise be too dangerous for humans, such as extreme weather or after-hours, significantly boosting productivity and project timelines without compromising human safety.

Beyond Safety: A Blueprint for Efficiency and Innovation

While safety is paramount, the benefits of remote control construction technology extend far beyond merely reducing risks. This technological leap also promises to:

- Improve Precision and Quality: Advanced sensors, high-definition cameras, and haptic feedback systems provide operators with detailed information, allowing for more precise movements and higher quality work than might be achievable under stressful, on-site conditions.

- Address Labor Shortages: By making construction work less physically demanding and hazardous, it can attract a new generation of skilled operators, including those who might not traditionally consider a career in construction. This broadens the talent pool significantly.

- Enhance Data Collection and Analytics: Remotely operated machinery can be equipped with sophisticated data logging capabilities, providing valuable insights into performance, efficiency, and project progress. This data can then be used for predictive maintenance, optimizing future operations, and even integrating with AI for autonomous task execution.

- Enable Work in Inaccessible Areas: Construction projects in remote, high-altitude, or otherwise difficult-to-reach locations become more feasible and cost-effective when human presence on-site is minimized.

Tokushima and Miyoshi: A Glimpse into Tomorrow

The demonstration in Tokushima, Miyoshi, serves as a powerful testament to the practical application of this visionary technology. It's not just a concept; it's a tangible solution being tested and refined in real-world scenarios. Such showcases are crucial for building confidence in these new systems, for training the next generation of operators, and for paving the way for wider adoption across the industry.

This event underscores Japan's commitment to leveraging technology to solve pressing societal challenges, from an aging workforce to the need for robust infrastructure development in a disaster-prone nation. By investing in and demonstrating such innovations, regions like Tokushima are not just building roads and bridges; they are building the framework for a smarter, safer, and more sustainable future.

Building a Future, Remotely Controlled

The implications of remote control technology in construction are immense. We are on the cusp of an era where construction sites are no longer defined by inherent danger but by intelligent machines guided by skilled human operators from secure locations. This fusion of human expertise and robotic precision promises to redefine how infrastructure is built, making it safer, faster, and more efficient than ever before. The path laid out in Tokushima, Miyoshi, is a clear signal: the future of construction is here, and it's being built remotely.

Comments

Post a Comment